Скачать с ютуб Rebuilding stub shaft on Sumo Trio packer roller. в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок Rebuilding stub shaft on Sumo Trio packer roller. в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Rebuilding stub shaft on Sumo Trio packer roller. или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Rebuilding stub shaft on Sumo Trio packer roller. в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Rebuilding stub shaft on Sumo Trio packer roller.

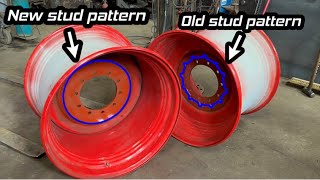

In this video I rebuild a worn down stub shaft on the end of a Sumo trio cultivator packer roller. Firstly, the collars are removed from the shafts to expose a portion that is unworn. I decide I can use this to make something to centralise my line borer. I flame cut some 102mm circles on the CNC table from 30mm plate and start making a clamping system to clamp onto the good part of the shaft. The billets are put into the lathe and machined down to 100mm diameter with a step also machined onto them. I cut off and clean up a short length of tube that fits over the step on the circles and weld them together. I then drill and reamer one end to 40mm to suit my line boring bar and the other to 60mm to suit the good part of the stub shaft. Next, I set the part up on the milling machine to mill, drill and tap the bolt holes for the clamping bolt, I use an M10 cap head bolt. After the holes are made, I cut through one side with the grinder to allow it to be pulled together and clamp on the shaft. I then start setting up the clamp and bar. I decide its too difficult to get an idea if the bar is running parallel with the packer, so I set up bearings on my bench and sit the packer onto them so I can spin the whole thing. Once I’m happy the bar is something like I can slide the bearing set on. New longer stands needed to be made to mount the bearings on. When everything is finally mounted, I can start machining the shaft down. I take 2 cuts off the shaft to start with to give me some depth of weld. I run welds all the way around the shaft to rebuild it and then machine back to 60mm. I had a few issues with rigidity so this was done with several light passed. The bearing was a little tight so I had to polish a little bit off with emery tape and sanding wheel. Thanks for watching. Hope you enjoyed the video.