Скачать с ютуб How To Convert DC to AC Motor Effectively | Supplied by John Brooks в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок How To Convert DC to AC Motor Effectively | Supplied by John Brooks в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно How To Convert DC to AC Motor Effectively | Supplied by John Brooks или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон How To Convert DC to AC Motor Effectively | Supplied by John Brooks в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

How To Convert DC to AC Motor Effectively | Supplied by John Brooks

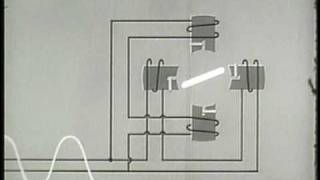

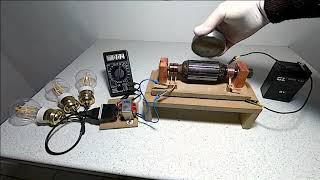

Trying to find the perfect electric motor for an industrial application can be tough. You want something that an expert would recommend, but you also want to weigh the advantages and disadvantages of DC and AC motors. The use of DC motors was once very popular in the industry world. This was because they had the ability to run at a speed that was set by a variable controller and they could reach full torque from the base speed. DC motors have traditionally been used in high torque processing applications such as paper machines and winders, rubber & plastic extruders, cranes and hoists, dynamometers, metal processing, and traction to name a few. DC motors are not cheap, though. They cost more upfront and require a considerable amount of maintenance. Historically, DC motors were your only option. With the introduction of AC motors, they are becoming a preferred choice due to their high performance, ease of maintenance and lower total cost of ownership. There are several key distinctions between AC and DC motors. The most apparent one is the type of current each motor uses to generate energy - alternating current for AC motors and direct current for DC motors. AC motors usually have a higher power output and are more efficient, while DC motors boast speed control and a wider constant torque range. Additionally, AC motors come in either single- or three-phase configurations, while all DC motors are single-phase in the smaller kilowatt ranges up to 2.2kw. What if you could upgrade your DC motor to an AC motor, reduce your maintenance costs and improve your overall equipment performance? Retrofitting a DC Motor is considered to be difficult. Designing a new product to perform efficiently and effectively while adhering to space constraints can also be challenging. To address this challenge there is a new Generation 3 Baldor-Reliance® RPM AC motor. RPM AC is a high-performance variable speed AC motor designed specifically to replace DC motors and its power-dense so it fits in spaces standard AC Motors just cannot. Like all DC motors, RPM AC will run with a drive, provide constant torque to zero speed, can handle wide constant HP speed ranges, and has dynamic response and high-speed capabilities. RPM AC is a product offering that is truly unique and differentiated in the marketplace for its power density, high performance, and problem-solving abilities. Certain features that improve variable speed performance are now included as standard such as shaft grounding brushes, insulated bearings, and QR codes on the nameplate that provide drive configuration data making start-up easier. RPM AC motors are offered in both induction and permanent magnet rotor designs. The permanent magnet rotor can further reduce the size of your machine to fit the tightest spaces or can provide ultra-premium efficient IE5 technology that will save you significant costs in your energy bills. The Ability Smart Sensor is easily mounted to these motors to wirelessly and economically monitor the health and performance of not only the motor but the entire drive train. Ready to make the switch? With RPM AC, we make the selection process easy through a web-based configurator that is extremely user-friendly. Pertinent information such as sizing, dimensional drawings, nameplate information, and performance data is available with just a few clicks. Challenge us with your toughest processing applications that are still using a DC motor or where a standard AC motor simply won’t do, and we’ll show you how it can be converted to an RPM AC motor. Experience the performance gains with lower maintenance costs, lower energy bills, and lower total cost of ownership. Reach out to John Brooks engineering experts in Auckland, Wellington or Christchurch office to get local experts involved in your transition from DC to AC motor. Call today 📞Auckland 0800 48 49 50 📩 [email protected] 📞Wellington 0800 24 34 44 📩 [email protected] 📞Christchurch 0800 37 38 39 📩 [email protected] John Brooks has a wide range of expertise spread across 3 branches in Auckland, Wellington or Christchurch to help assist in selecting, modifying, and delivering solutions you can trust. If you are not sure which electric motor to select, contact your local branch, and a John Brooks representative will be in contact to discuss your needs and requirements. Visit our website www.johnbrooks.co.nz to explore over 5,000 industrial automation products we offer including Power Transmission, Gearboxes, Electric Motors, VSD & Controllers Automation Fluid Handling