Скачать с ютуб Mooring Operation ship в хорошем качестве

mooring operation ship

mooring operation

mooring

mooring rope splicing

mooring rope breaking

mooring winch operation

mooring operation ship accident

mooring operation ship in hindi

mooring operation ship explained

mooring operation aft station

mooring operation containership

mooring operations training

mooring operation forward

ships

navigation

merchant navy

sailor vikas

navy

nautical

deck

life at sea

mariners

ship accidents

mooring accidents

deck operations

Скачать бесплатно и смотреть ютуб-видео без блокировок Mooring Operation ship в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Mooring Operation ship или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Mooring Operation ship в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Mooring Operation ship

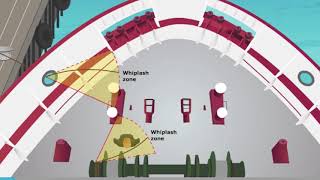

#mooring #ships When a master receives the name of a port at sea for the next visit, preplanning starts. Ships navigating officers begin getting information about this port from various publications. A "Guide to port entry" provides valuable information of more than 6000 ports worldwide, which laid out in a logical sequence. Another source of data is the "Sailing direction"- often referred to as "Pilots". Deployment and monitoring of moorings The master should ensure that mooring operations (including interaction with Tugs) are carried out carefully, and the following items are appropriately addressed: Suitable planning and supervision Proper communication Competency of personnel Sufficient members in the mooring teams Familiarity with any specific shore requirements relating to shore moorings, passing traffic and tidal/weather conditions All mooring equipment and practices should comply with applicable guidelines (for Tankers as per OCIMF) and local regulations. Any unsafe situations should be identified, evaluated, and recorded in the Safety & Health Committee Meeting. Corrective actions need to be implemented as necessary. Before conducting any mooring operation all mooring gears and communication systems should be tried out. When a pilot arrives mooring plan should be discussed and agreed. Officers in charge of mooring operations must clearly understand the plan and prepare accordingly. For safely moor a ship the effects of wind, underwater current, effects of tide, under keel clearance concerning ships draught, and surging effect of passing ships all must be properly taken into account. Before arrival, the berth deck crew should arrange all mooring lines in such a manner so that these are readily available to deploy. Definition of common mooring lines explained below: Breast lines – Mooring lines leading ashore as perpendicular to the ship fore and aft line. Breast lines restrain the ship in one direction (off the berth). Note: Due to collision with shore gantry cranes, breast lines are not usually used in container terminals. Head lines – Mooring lines leading ashore from the fore-end or forecastle of a ship, often at an angle of about 45 degrees to the fore and aft line. Spring lines – Mooring lines leading in a nearly fore and aft direction, the purpose of which is to prevent longitudinal movement (surge) of the ship while in the berth. Spring lines restrain the vessels in two directions: headsprings prevent forward motion and back springs aft motion. Stern lines – Mooring lines leading ashore from the after the end or poop of a ship, often at an angle of about 45 degrees to the fore and aft line. Safety of crew during mooring operations Anchor & mooring equipment Tanker vessels engaging in different mooring patterns should be particularly careful with the mooring arrangement and preparation onboard with particular emphasis on Use of remote control position for operating winches (where applicable) Clear layout on deck prior operations The use of proper personal protective equipment Identification and monitoring of dangerous zones during mooring operations Quick and close communication between stations Tanker vessels engaging in different mooring patterns/arrangements should carry out a Formal Risk Assessment for each type, to assess and minimize the crew associated with the operation. Such risk assessments are to be reviewed before similar subsequent operations and any additional identified risks suitably managed and recorded. Maintenance of mooring equipment (Tankers) Brake Testing: Mooring equipment onboard should be maintained in good working condition so as to secure safety in mooring operations. Planned Maintenance Schedules include a requirement for Annual Brake Testing of all mooring winches using the test kit provided onboard. This includes testing Brake Holding Power / Rendering and adjustment to ensure rendering of mooring winch brakes at optimum stress to reduce the risk of injury from an overstressed mooring. Such procedures must meet applicable OCIMF guidelines, and winch brake should be marked after testing and brakes to be set at the correct tension setting while in use. Record of spare inventory is to be kept on board and used spares replenished. Replacement of Wires, Ropes and Tails (Tankers) For all Mooring ropes, Wires, Tails, and Shackles, a record of certificates, replacement date, and specific winches to which they are fitted, is to be maintained. The PMS procedure includes inspection intervals for all mooring equipment and also covers End-to-End and Renewal procedures. Specific intensive vessel trading patterns may warrant a more frequent change of spares such as mooring rope tails. Such intervals may be shorter than that prescribed in OCIMF guidelines. Standard for replacing Mooring Wires on some Tankers designated as below. Head / Stern lines: Replacing: 7.5 years & Reversing end to end: 3.75 years Spring / Breast lines: Replacing: 5 years & Reversing: 2.5 years