Скачать с ютуб Delta DVP PLC Temperature PID- GPWM and ISP Soft Part 2 в хорошем качестве

allinclusive

Programming

service

Solution

SCADA

PLC

HMI

Servo

servodrive

steppers

VFD

factory

automation

inverter

foodandbeverage

engineering

troubleshooting

training

inductionmotor

software

programming

datalogger

pharmaceutical

TIA Portal V17

PID

PID Compact

PID Temperature

How to

Analog IO

Configure

Web Server

Delta

ISPSoft

04AD-S

04DA-S

4-20mA

0-10vdc

DVP 04TC

DVP04RTD

Temperature PID

GPWM

MV

PV

SP

proportional integral derivative

Pulse Width Modulation

Скачать бесплатно и смотреть ютуб-видео без блокировок Delta DVP PLC Temperature PID- GPWM and ISP Soft Part 2 в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Delta DVP PLC Temperature PID- GPWM and ISP Soft Part 2 или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Delta DVP PLC Temperature PID- GPWM and ISP Soft Part 2 в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Delta DVP PLC Temperature PID- GPWM and ISP Soft Part 2

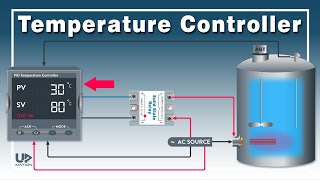

00:00 intro 0:15 start 6:8 program simulation 11:23 PID mode set PID = proportional integral derivative GPWM = General Pulse Width Modulation PWM = Pulse Width Modulation PV (process value/process variable), SV/SP (set value) and MV (manipulated output value) can be transferred to other measuring instruments. A cost corresponding to one temperature sensor can be reduced just by connecting a PV transfer signal to a recorder. Temperature PID: Step1, Read RAW Data of Temperature form Delta Analog input Step2, Display Temperature Unit= 0.1 = 10 Digital RAW Data/ 10 Digital RAW Value MAX: 2000, MIN 0 Temperature: 200, MIN 0 Analog input Chanel1: Sensor Connected, and CR#6 Step3, Configure PID Instruction Step4, Configure GPWM Heater Output: Y0 Blower Output: Y1 D0 = Digital RAW Value, Max = 2000 D2 = Actual Temperature Value, MAX =200 C PID = 16 bit DPID = 32 bit SV = D410 Setup PID MOD = D412 PV = D0 MV = D4, Pulse Width Reference D4 = Pulse Width D6 = Pulse Output Cycle Y0 = Heater output S3 = D500 S3.0 = D500 S3+1 = D501 S3+2 = D502 S3+3 = D503 S3+4 = D504 = PID Cont.MOD Delta DVP PLC PID Mod Setting 0: Automatic control 1: Forward control (E = SV - PV). 2: Reverse control (E = PV - SV). 3: Auto-tuning of parameter exclusively for the temperature control. The device will automatically become K4 when the auto-tuning is completed and KP, KI and KD is set with appropriate value (not available in the 32-bit instruction). 4: Exclusively for the adjusted temperature control (not available in the 32-bit instruction). 5: Automatic mode with MV upper/lower bound control. When MV reaches upper/lower bound, the accumulation of integral value stops. 7: Manual control 1: User set an MV. The accumulated integral value increases according to the error. It is suggested that the control mode should be used in a control environment which change more slowly.

![DELTA PLC ISPSOFT [ TEMPERATURE CONTROL ] PROGRAMMING](https://i.ytimg.com/vi/JDlzQxbG_JY/mqdefault.jpg)