Скачать с ютуб How iron is made animation | Karthi Explains в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок How iron is made animation | Karthi Explains в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно How iron is made animation | Karthi Explains или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон How iron is made animation | Karthi Explains в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

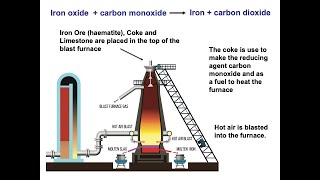

How iron is made animation | Karthi Explains

Welcome To Karthi Explains There are many steps involved in the making of iron but in this video, I simply explained 3 steps 1. The Ore Extraction 2. refining 3. The manufacturing process Before iron ore can be used in a blast furnace it must be extracted from the ground and partially refined to remove most of the impurities much of the world's iron ore is extracted through open pit mining in which the surface of the ground is removed by heavy machines Refining process - the mined ore is crushed and sorted the best grades of ore containing over 60 % iron and the lesser grades are treated or refined by crushing washing with water to float sand and clay away magnetic separation palletizing sintering etc The refined ore is then transported to the blast furnace site The manufacturing process - after refining the iron ore is blended with coke and limestone and goes to the blast furnace a blast furnace is a tower-shaped structure made of steel and lined with refractory or heat resistant bricks the mixture of iron ore coke and limestone enters to the top of the furnace at the bottom of the furnace a very hot air is blown or blasted through the nozzles called Tuyeres the coke burn in the presence of the hot air the oxygen in the air reacts with the carbon in the coke to form carbon monoxide then reacts with the iron ore to form carbon dioxide and pure iron Separating the iron from the slag Melted iron sinks to the bottom of the furnace the limestone combines with the rock and other impurities in the ore to form a slag which is lighter than iron and floats on the top iron and slag are drawn off separately from the bottom of the furnace the melted iron might go to a further alloying process or might be cast into ingots called pigs the slag is carried away for disposal and the hot gases produced in chemical reactions are drawn off at the top or rooted to a gas cleaning plant and this is how iron is made 0:00 - Introduction 0:38 - Pig Iron 0:50 - Raw Materials 1:17 - Steps 1:27 - 1. Extraction Of Iron ore 1:41 - 2. Refining Of Iron ore 2:02 - 3. Manufacturing Process 2:09 - Blast Furnace 2:55 - Final Product 3:00 - Disposal Of Slag