Скачать с ютуб How Do You Bend a 90 in Conduit? в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок How Do You Bend a 90 in Conduit? в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно How Do You Bend a 90 in Conduit? или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон How Do You Bend a 90 in Conduit? в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

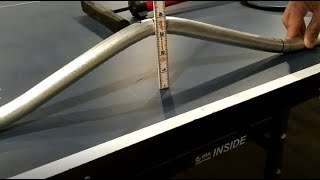

How Do You Bend a 90 in Conduit?

Installing conduit is one of the primary tasks of a commercial/industrial electrician. Without it, wire can’t get from one point to another! And bending a 90 degree bend in conduit is one of the first skills learned when starting to bend conduit. Most of us electricians start out learning to bend on steel EMT conduit. But what about Aluminum EMT conduit? Is there a difference? In todays episode of Electrician U, Dustin Stelzer talks a bit about the pros and cons of each as well as the necessary steps to successfully bending a 90-degree bend. 🤘⚡️EU Learning System⚡️🤘 For Individuals --- https://electricianu.com/learning-sys... For Businesses --- https://electricianu.com/learning-sys... -Video courses on every side of the electrical trade (theory, code, safety, wiring, install, troubleshooting, leadership, and more) -Practice exams for 2017, 2020, 2023 code -YouTube videos categorized and searchable -Audio lessons -Forum -Business version has admin portal and ability to assign learning to technicians and monitor progress -Any business size from 2 techs to 2,000! 🎓💡CONTINUING EDUCATION💡🎓 Sign up here --- https://electricianu.com/continuing-e... -State Approved -Video Based ✍📝PRACTICE EXAMS📝✍ Get them here --- https://www.electricianu.com/electric... -2017, 2020, and 2023 NEC versions -Online Residential Wireman Exam -Online Journeyman Exam -Online Master Exam -300 Question Online Code Cannon (not license specific, all code) -Take as many times as you want -All of the above come with printable PDFs 🎤🎧PODCAST🎧🎤 Spotify: https://open.spotify.com/show/7ldCwdx... Apple Podcast: https://podcasts.apple.com/us/podcast... 📱👍SOCIALS👍📱 TikTok - / electricianu Instagram - / electrician_u Facebook - / theelectricianu Reddit - / electricianu Rumble - https://rumble.com/c/ElectricianU Discord - / discord 🎧🎹Music, Editing, and Videography by Drake Descant and Rob LeBlanc🎹🎧 ⚡🔨SPONSOR: PENN ALUMINUM🔨⚡ https://www.pennconduit.com/ #electrician #electrical #electricity First let’s talk about Penn Aluminum, todays sponsor. Penn Aluminum produces some of the best Aluminum EMT conduit available. But why use aluminum EMT instead of steel? Its considerably lighter than its steel counterpart and easier to bend, which results in much less stress on the installing electrician and leads to much greater productivity. In todays market, aluminum EMT conduit is anywhere from 10% to 20% cheaper than steel EMT, which can add considerable cost SAVINGS to a project. However, one of the downfalls to using aluminum EMT is that it IS harder to pull wire into. It just seems that the wire (or the wire pulling apparatus) gets hung up on the inside of the pipe. Penn Aluminum has developed a special coating for the inside of the conduit called Blue Lightning. This coating acts much like Teflon making the inside of the pipe super slick and wire goes in much easier even than standard steel EMT. Check out Penn Aluminums website- they have a ton of products that will certainly meet your conduit needs! Great company! The first step in bending a 90 in conduit is to establish a length. Once a length is established, you will need to mark this on the conduit- lets say 36”. The next step in the process is to apply the deduct (this is the length required where the conduit will actually SWEEP and that will need to be considered in our calculation). Standard deducts are ½”- 5”, ¾”- 6”, 1”- 8”. Subtract this distance from your original mark- for our 36” 90, we will make another mark on our conduit at 30”. Hook the bender onto the conduit with the open end of the bender FACING the direction you hooked your tape measure on. Place the ARROW on the bender handle on the 30” mark (distance needed for 90 MINUS the DEDUCT). A very important step in the bending process is to apply FOOT pressure, not just PULL with your arms. So, step on the bender shoe, while pulling on the bender handle until the measured portion of the conduit is vertical in the air. Using a torpedo level, continue to adjust the vertical portion until it is at 90 degrees. That’s it! Bend completed! Not to worry if you OVERBEND, just step on the portion of the conduit still on the ground and PUSH the vertical portion of the conduit AWAY from you until it is at 90 degrees.