Скачать с ютуб Temper Bead Welding. When to use and how to avoid associated crack. в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок Temper Bead Welding. When to use and how to avoid associated crack. в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Temper Bead Welding. When to use and how to avoid associated crack. или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Temper Bead Welding. When to use and how to avoid associated crack. в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Temper Bead Welding. When to use and how to avoid associated crack.

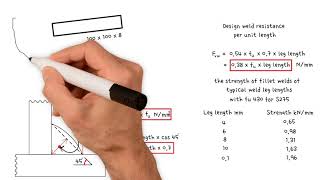

Temper Bead Welding. When to use and how to avoid associated crack. Temper bead welding is a technique used to reduce the hardness and potential brittleness in the heat-affected zone (HAZ) of a weld joint. This technique is typically used in welding high-strength steels, such as those used in pressure vessels and offshore structures. The process involves depositing a weld pass that partially overlaps the previous weld pass, using a lower heat input than the initial pass. This helps to control the heat input and reduce the risk of cracking in the HAZ. The partially overlapped weld passes are referred to as "temper beads." To avoid associated cracking, here are some tips to keep in mind: Proper preheat: Make sure that the base metal is heated to the appropriate temperature before welding. This will help to reduce the cooling rate and prevent cracking. Control heat input: Use the appropriate welding parameters, such as current and travel speed, to maintain a consistent heat input. This will help to prevent excessive heating of the base metal and HAZ. Proper cooling: Allow the welded joint to cool slowly and uniformly to avoid thermal shock, which can lead to cracking. Select proper filler metals: Use a filler metal that has a low carbon equivalent to reduce the risk of cracking. Avoid abrupt changes in joint geometry: Abrupt changes in joint geometry can create stress concentrations, which can lead to cracking. Use gradual transitions when changing the joint geometry. In summary, temper bead welding can be an effective technique for reducing the risk of cracking in high-strength steels. However, it requires careful attention to welding parameters and joint geometry to avoid associated cracking. #temperbeadwelding #weldingtechniques #weldingprocess #weldingtips #weldingtricks #weldingcracks #weldinghardness #metalfabrication #pressurevessels #offshorestructures #weldingvideos