Скачать с ютуб Single Stroke Honing Machine | iHone VR500-6S | 6th Generation | Precision Personified в хорошем качестве

Single Pass Honing Machine

Single Pass Honing

Single Stroke Honing

Honing Machine

Single Pass Honing Tool

Diamond Reaming

Bore Finishing

Hole Finishing

Super finishing

CNC Single Pass Honing Machine

Diameter Control

Cylindricity

Circularity

Bore Taper

Multi pass honing

multi stroke honing

Single Pass Hone

Honing Process

Скачать бесплатно и смотреть ютуб-видео без блокировок Single Stroke Honing Machine | iHone VR500-6S | 6th Generation | Precision Personified в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Single Stroke Honing Machine | iHone VR500-6S | 6th Generation | Precision Personified или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Single Stroke Honing Machine | iHone VR500-6S | 6th Generation | Precision Personified в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Single Stroke Honing Machine | iHone VR500-6S | 6th Generation | Precision Personified

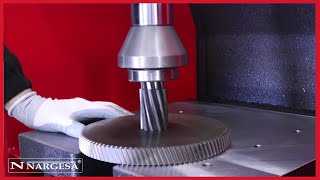

🚀 Unlocking Precision: Single Pass Honing with Insight's iHones! 💎 The 6th Generation of iHone VR-S Series! ✅ Enhanced in every aspect, robustness to precision to ergonomics to aesthetics, and a host of nuanced upgradations! Ready to explore Single Pass Honing ⁉️ This high-productivity bore-finishing process achieves remarkable precision in bore size, roundness, cylindricity, and surface finish. Let’s dive into how it works and why Insight's iHone VR-S Series is a leader in the industry. The Process: Single-pass honing employs fixed-diameter tools coated with diamond or cubic boron nitride (CBN) abrasives. Unlike traditional multi-pass methods, this technique utilizes a single in-and-out stroke for efficient material removal. And, these tools with Diamond / CBN abrasives offer exceptional durability, with tool life going from 50,000 to up to a million parts; we have seen more! Material Removal: The process typically removes between 0.025 mm to 0.075 mm. Progressive sizing ensures exceptional dimensional accuracy with bore sizes repeatable within ±0.001 mm and less (!). Oh yes, it can actually attain size tolerances of upto ±0.0005! Tight Tolerances: Bore Size & Roundness: Fixed tool sizes eliminate variability, maintaining both size and roundness, part after part! Cylindricity: Continuous strokes minimize misalignment errors, achieving tolerances as tight as 0.0005 mm. Surface Finish: Diamond-coated tools produce finishes around 0.05 to 0.15 Ra, essential for optimal lubrication and reduced friction. Cutting Mechanics: The combination of rotary and linear motion creates a micro-cutting action that efficiently removes material while minimizing heat generation and tool wear. Efficiency Redefined: With cycle times as low as 6-8 seconds per part and feed rates from 400 mm/min to 1500 mm/min, these machines can produce up to 600 parts per hour—ideal for high-volume production. Well of course, the time is a function of diameter & length of the bore. Insight's iHone VR-S Series Robust Construction: Vibration-resistant thermo-symmetric cast structures for enhanced performance. Super-precision Drives: Headstock spindles, Feed-drives, B-Axis, all exude precision in its true form. Easy-to-Use Control Systems: It's a cake walk to set the programs up and set the machine up for running. Let’s Connect! Looking for fast, consistent, and reliable bore finishing solutions? Let’s chat about how iHones can elevate your manufacturing game. Reach out at https://www.insight-technologies.in/C... While at it, also take a look at knowledge section & gallery! Knowledge: https://www.insight-technologies.in/K... Gallery: https://www.insight-technologies.in/G... Join us on this journey toward precision—let's refine your manufacturing capabilities together! 🚀✨ 🔖 #SinglePassHoning #PrecisionEngineering #ManufacturingExcellence #CostEfficiency #BoreFinishing #HoneFinishing #PrecisionMachining • Single Stroke Honing Machine | iHone ...