Скачать с ютуб Design & Operating Principle of Differential Pressure Guage в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок Design & Operating Principle of Differential Pressure Guage в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Design & Operating Principle of Differential Pressure Guage или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Design & Operating Principle of Differential Pressure Guage в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

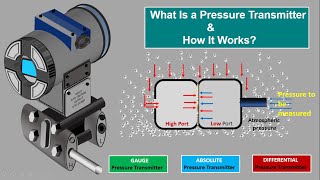

Design & Operating Principle of Differential Pressure Guage

In my previous video i told the operation of diaphragm pressure gauge, and in this video i want to tell about the design and operation of differential pressure guage. First of all we will see what is differential pressure? Differential pressure, or DP, is simply the difference between two applied pressures. For example, if the pressure at point A equals 100 p s i and the pressure at point B equals 60 p s i, then the differential pressure is 40 p s i that is (100 p s i minus 60 p s i). Do you know what is the differential pressure guage? A differential pressure gauge is a visual indicator, designed to measure the difference between two pressure points within a process system. The gauge usually has two inlet ports that are each connected to the pressure points being monitored. Now we will see the operation of the differential pressure guage? when Process pressures are applied to the low pressure chamber and high pressure chamber. The area between the two diaphragms is filled with a transmitting fluid. Any pressure differential will deflect the diaphragm and the deflection is hydraulically transmitted to the other diaphragm by the transmitting fluid. The deflection of the diaphragm is transmitted to the pointer by means of a rotating axle that provides frictionless transmission and a metal to metal seal with the help of links. A pressure greater than the full scale will close the valve, thus discontinuing the transmission of pressure. Both diaphragms rest on a liquid cushion that allows the instrument to withstand process pressure up to the maximum pressure rating of the instrument. Differential pressure gauges are used to measure the flow of a liquid inside a pipe. An orifice plate, venturi, or flow nozzle is often used to reduce the diameter inside a pipe. The differential pressure gauge measures the flow rate by finding the difference in pressure before and after the orifice. Differential pressure gauges are an easy way to get a visual indication of process flow. Thanks for watching, Please subscribe for more videos.

![Почему площадь сферы в четыре раза больше её тени? [3Blue1Brown]](https://i.ytimg.com/vi/JsrRqLK8zKg/mqdefault.jpg)