Скачать с ютуб What should be paid attention to in mold design with complex sliders for the automotive parts? в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок What should be paid attention to in mold design with complex sliders for the automotive parts? в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно What should be paid attention to in mold design with complex sliders for the automotive parts? или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон What should be paid attention to in mold design with complex sliders for the automotive parts? в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

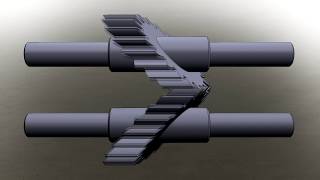

What should be paid attention to in mold design with complex sliders for the automotive parts?

1. Complexity: The sliders structure should be designed to accommodate the required shape and features of the part, while also minimizing complexity to ensure ease of manufacturing and assembly. 2. Material flow: The design should allow for proper material flow during the injection molding process, avoiding any potential flow restrictions or quality issues. 3. Demolding forces: The sliders mechanism should be strong enough to withstand the demolding forces and prevent any potential part deformation or damage during the ejection process. 4. Cooling: Proper cooling channels should be integrated into the sliders structure to ensure efficient and uniform cooling of the molded part, reducing cycle times and improving overall part quality. 5. Durability: The sliders components should be designed to withstand the rigors of the injection molding process, ensuring long-term durability and minimal maintenance requirements. By carefully considering these factors, designers can ensure that the slidersstructure for automotive parts is optimized for both manufacturing and part quality. Video from the Internet, welcome original creators to contact us Please visit www.longtermmould.com, or email:[email protected]