Скачать с ютуб Mastercam 2023: 3D Hair Dryer Machining Tutorial в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок Mastercam 2023: 3D Hair Dryer Machining Tutorial в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Mastercam 2023: 3D Hair Dryer Machining Tutorial или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Mastercam 2023: 3D Hair Dryer Machining Tutorial в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

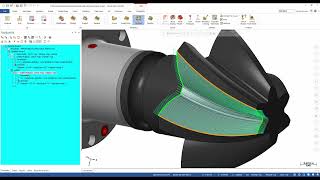

Mastercam 2023: 3D Hair Dryer Machining Tutorial

Mastercam 2023: 3D Hair Dryer Machining Tutorial *Mastercam 2023: 3D Hair Dryer Machining Tutorial* *Introduction:* In this tutorial, we'll guide you through the process of creating a hair dryer housing using Mastercam 2023. We'll cover 3D modeling, toolpath generation, and simulation to ensure a successful machining process. *Step 1: Import or Create the 3D Model:* * *Import:* If you have a pre-designed 3D model of the hair dryer housing, import it into Mastercam. * *Create:* If you don't have a model, use Mastercam's 3D modeling tools to create the housing geometry, including the body, handle, and air outlet. *Step 2: Define Machining Parameters:* * *Stock Setup:* Define the size and shape of the raw material (stock) you'll be using for machining. * *Tool Selection:* Choose appropriate cutting tools for different machining operations (e.g., roughing, finishing, drilling). * *Machining Parameters:* Set cutting parameters like feed rates, spindle speeds, and depth of cuts based on the tool, material, and desired finish. *Step 3: Generate Toolpaths:* * *Roughing:* Create toolpaths to remove bulk material from the stock. Use strategies like surface roughing or pocketing. * *Finishing:* Generate toolpaths to achieve a smooth surface finish. Consider using contouring or finishing strategies. * *Drilling:* Create toolpaths for drilling holes for screws, vents, or other features. *Step 4: Simulate Toolpaths:* * Use Mastercam's simulation tools to visualize the toolpaths and identify potential collisions or errors. * Make necessary adjustments to the toolpaths if needed. *Step 5: Generate G-Code:* * Create G-code instructions for your CNC machine based on the generated toolpaths. * Review the G-code to ensure it's accurate and error-free. *Step 6: Machining:* * Transfer the G-code to your CNC machine and run the program. * Monitor the machining process and make any necessary adjustments. *Additional Tips:* * *Consider Material:* The choice of material (e.g., plastic, metal) will affect machining parameters and tool selection. * *Optimize Toolpaths:* Use Mastercam's optimization tools to improve machining efficiency and reduce tool wear. * *Verify Dimensions:* After machining, measure the finished part to ensure it meets the design specifications. *By following these steps and utilizing Mastercam's powerful features, you can successfully create a hair dryer housing using 3D machining.* *Would you like to delve deeper into any specific aspect of this tutorial?*