Скачать с ютуб Making A Quick Change Tool Post Without A Mill в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок Making A Quick Change Tool Post Without A Mill в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Making A Quick Change Tool Post Without A Mill или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Making A Quick Change Tool Post Without A Mill в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

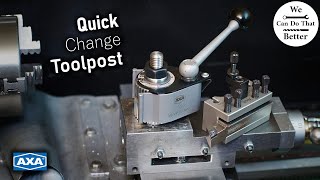

Making A Quick Change Tool Post Without A Mill

This is my design and build of a quick change tool post for my Sieg mini lathe. Without access to a rigid mill, I had to persevere with how I cut the features of the tool post, including the dovetails. A Few things that I didn't put into the commentary but I think should be addressed. The tool post that I made here, and the one that I will be moving to my Sherline are made from aluminium. On the whole, I think for mini lathe use aluminium is perfectly adequate, but for any larger lathes, steel is the way to go. The only problem that I have ever encountered with the aluminium tool post was the wearing down of the top edge of the dovetail by the adjustment nut, and this should be avoided by the use of steel in the new tool post. The design on this tool post uses a cam and piston to push the tool holder and lock it into position. I think this design is perfectly adequate for the light use that I can do on my lathe, but for heavier work loads, the wedge style in the way to go, although they would be harder to replicate. Something that caught my surprise in the sped up footage was that my vise must have come a little loose over time. I hardly noticed when I was cutting but became very evident in the sped up footage. Finally in some parts of the turning of the large aluminium stock, the tool would have the tendency to bite into the aluminium. This is something that I have noticed occurs when the bots that hold the retaining strips come a little loose. this generally does not occur, but vibration when I turn down square stock always seems to loosen them. When drilling, since my lathe runs at a fixed rpm (as I set the lathe up to cut mainly Acrylic) the speeds will generally not be suited for the low rpm the larger twist drills call for. Timestamps: 0:00 - Introduction 1:36 - Machining The Body 4:13 - Making The Dovetails 7:22 - Machining The Inner Components 13:38 - Assembly Soundtrack Used: AERØHEAD - Fragments • Fragments AERØHEAD - Lights of Elysium • Lights of Elysium