Скачать с ютуб DEVELOPMENT AND TESTING OF A 10 MWe SUPERCRITICAL CO2 TURBINE IN A 1 MWe FLOW LOOP в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок DEVELOPMENT AND TESTING OF A 10 MWe SUPERCRITICAL CO2 TURBINE IN A 1 MWe FLOW LOOP в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно DEVELOPMENT AND TESTING OF A 10 MWe SUPERCRITICAL CO2 TURBINE IN A 1 MWe FLOW LOOP или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон DEVELOPMENT AND TESTING OF A 10 MWe SUPERCRITICAL CO2 TURBINE IN A 1 MWe FLOW LOOP в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

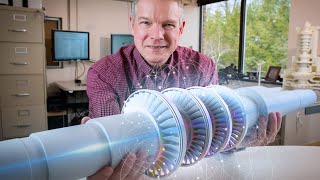

DEVELOPMENT AND TESTING OF A 10 MWe SUPERCRITICAL CO2 TURBINE IN A 1 MWe FLOW LOOP

sCO2 power cycles offer improved cycle efficiencies compared with traditional steam Rankine cycles. However, the turbomachinery required to support such a cycle does not exist at a commercial scale and requires development. This paper describes a new 10 MWe scale sCO2 turbine was developed and demonstrated in an sCO2 closed-loop recompression Brayton cycle. Since this turbine was developed for Concentrating Solar Power (CSP) applications, a target inlet temperature of over 700°C was chosen using funding from the US DOE SunShot initiative and industry partners. However, it can be applied to traditional heat sources such as natural gas, coal, and nuclear power. Traditional Rankine steam cycle thermal efficiencies are typically in the 35-40% range, but can be as high as 45% for advanced ultra-supercritical steam cycles. The sCO2 cycle can approach 50% thermal efficiency using externally fired heat sources. Furthermore, this cycle is also well suited for bottoming cycle waste heat recovery applications, which typically operate at lower temperatures. The high-power density and lower thermal mass of the sCO2 cycle results in compact, high-efficiency power blocks that can respond quickly to transient environmental changes and transient operation, a particular advantage for solar, waste heat, and ship-board applications. The power density of the turbine is significantly greater than traditional steam turbines and is comparable to liquid rocket engine turbo pumps. This paper describes the design and construction of the turbine and provides additional testing of the10 MWe turbine in a 1 MWe test facility including a description of rotordynamics, thermal management, rotor aero and mechanical design, shaft-end and casing seals, bearings, and couplings. Test data for the turbine is included, as it achieves its operational goal of 715°C, 250 bara, and 27,000 rpm.