Скачать с ютуб Piano Action: Kawai Millenium III ABS-Carbon Piano Action в хорошем качестве

piano

piano action

piano action model

piano action diagram

piano action regulation

piano action mechanism

how pianos work

grand piano

wippen

repetition lever

jack

hammer

damper

Piano

piano action parts

piano action cradle

piano action lubricant

piano action keyboard

piano action slow motion

piano action animation

piano action bracket

piano action explained

Piano (Musical Instrument)

Piano Regulating

Piano Repair

Piano Tuning

Скачать бесплатно и смотреть ютуб-видео без блокировок Piano Action: Kawai Millenium III ABS-Carbon Piano Action в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Piano Action: Kawai Millenium III ABS-Carbon Piano Action или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Piano Action: Kawai Millenium III ABS-Carbon Piano Action в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

Piano Action: Kawai Millenium III ABS-Carbon Piano Action

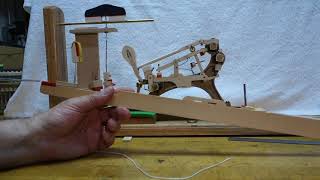

#pianoaction #piano #kawai Piano Action: Kawai Millenium III ABS-Carbon Piano Action Learn More: https://kawaius.com/technology/millen... --- Connect with Kawai Pianos on: Twitter: / kawaipianos Facebook: / kawaipianosus Pinterest: / kawaipianos http://www.kawaius.com This is one of most important piano videos you'll ever see. It will change the way you think about piano quality. And it will keep you from making a BIG mistake on your next piano purchase. Let's start with a brief history lesson that will affect your wallet. THIS... is a piano ACTION. The "action" is the mechanism inside a piano that transforms your touch on a key into a hammer strike that produces musical sound. Back in the early 18th century, an Italian inventor named Bartolomeo Christofori created the first piano action. It was a great start, but quite primitive and not very stable. In the 19th century, Sebastian Erard developed this piano action that was a major evolution from "old" to "new." Erard's design offered better performance and a more enjoyable playing experience. But it still didn't address the issue of stability. Both of these early actions were made entirely of wood. That's because wood was the only material the early piano makers had available to craft the thousands of intricate parts needed for a piano action. The first half of the 20th Century brought even more evolution. Many piano actions of that period were based on this design which was also made of all wooden action parts. These actions promised higher performance and better control of touch and tone. Yet, the stability problems remained. Then something surprising happened in the piano industry. After 250 years of steady progress in the art of the piano, evolution stopped. Progress came to a virtual halt. It was as though piano makers believed that a piano couldn't get any better. Meanwhile, other industries kept evolving rapidly. In the tennis world, manufacturers of wooden rackets began moving to composite materials (such as graphite, kevlar and eventually carbon fiber) to improve performance. By the 1980s, wooden rackets were obsolete. The golf industry made a similar move away from traditional wood drivers to other materials that could provide a longer, more stable tee shot. Wooden drivers became "relics of the past" as golf moved on to modern materials. While these and other industries kept advancing, piano makers seemed content to maintain the status quo… except for one: KAWAI. As early as the 1960s, Kawai craftsmen recognized the serious problems associated with wood. Wood was ideal for many of the "sound-producing" components of a piano (such as the soundboard, rim and hammers), but it was problematic for many of the major internal components of a piano action. The problem? Wood wasn't stable. It could break under high stress and would continually swell and shrink with changes in humidity. With over 8000 parts in a piano action, these shortcomings were unacceptable. Kawai design engineers knew that the mechanical parts of piano action required exacting and unchanging precision… and that wooden parts could never maintain that level of precision over time. With that in mind, they set out to solve a major wood-related problem: the flawed hammer strike. To create excellent tone and touch, the hammers must strike the strings perfectly every time, over the course of time. If the alignment of the hammer is altered, even by as little as one millimeter due to breakage or the swelling or shrinking of any component, the piano's tone and touch deteriorates and the player's enjoyment and performance fades. To solve this problem, Kawai invested millions of dollars to develop action parts made of composite materials. Composite parts are more durable than wood and virtually impervious to swelling and shrinking due to humidity. By the 1990s, these efforts resulted in the Kawai Ultra-Responsive Action -- the fourth major evolution of touch and tone in the history of the piano. With composite parts, Kawai actions were far more stable than conventional all-wooden actions. Kawai hammers would strike the strings with greater precision despite changes in humidity. And Kawai pianos maintained better touch and tone over time than any other pianos. By the end of the 20th century, Kawai had established itself as the technological leader in the global piano industry. But evolution didn't end there. Kawai continued to evolve into the 21st Century with the introduction of carbon composites to improve pianotouch and responsiveness. As carbon fiber found its way into modern aircraft, race cars, racing boats and performance cycling, it also played a major role in the development of Kawai's revolutionary Millennium III Action with ABS-Carbon.