Скачать с ютуб Computer Vision for Workplace Safety в хорошем качестве

Скачать бесплатно и смотреть ютуб-видео без блокировок Computer Vision for Workplace Safety в качестве 4к (2к / 1080p)

У нас вы можете посмотреть бесплатно Computer Vision for Workplace Safety или скачать в максимальном доступном качестве, которое было загружено на ютуб. Для скачивания выберите вариант из формы ниже:

Загрузить музыку / рингтон Computer Vision for Workplace Safety в формате MP3:

Если кнопки скачивания не

загрузились

НАЖМИТЕ ЗДЕСЬ или обновите страницу

Если возникают проблемы со скачиванием, пожалуйста напишите в поддержку по адресу внизу

страницы.

Спасибо за использование сервиса savevideohd.ru

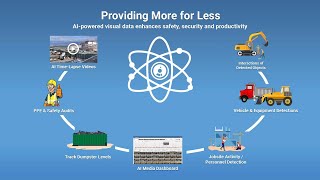

Computer Vision for Workplace Safety

How is computer vision used to e detect, classify, and recognize risks in the workplace? Learn more. This video was excerpted from a BenderU Webinar from Bender Insurance Services. Transcript Ana: Some tasks involved in computer vision would be detection, classification, and recognition. And we'll go into those individually coming up, but these are really the crux of our product. These are what is getting us to a state of understanding the safety risks in a warehouse. Ana: With detection, what it is is identifying important objects in an image or a video. So for our purposes, we have the bounding boxes around the objects in the frame, and it's identifying those regions of interest. Like our model has identified, this is something moving or something that I've been trained to think is important. So next slide. If you look closely that there are labels for each object in the scene. So they're also color coordinated, but like pallet boards are yellow, the person is green, forklift is a different shade of green. But basically we're just assigning names to the object and it's giving us a slightly clearer picture what's happening in the warehouse. Ana: But when we go to the next slide, we'll actually see that the model is learning and it's getting to a place of that understanding that is our goal. So with action recognition, we are understanding what is going on in the scene. You see the lightly shaded red box around the scene in the middle there, this is a safety event going on. And I would love if Kris could tell us what's going on in this video here. Kris: Absolutely. So as Ana mentioned, this is a clip straight from the AI. It found a number of safety hazards here. It boxed it and then it forwarded the clip. So then we go into some further review. Well, we can see the forklift raises up that pallet to stack it on top of the other pallets, and there's an employee rather close by. And what the AI actually grabbed was the employee came too close to the forklift while the forklift had a load raised. There are a lot of different measurements and things that are all being considered in this. Kris: Another thing we noticed just from this clip, it's a crowded area. It's a high volume walkway right now. But even the stacked pallets, you can see those continue to slide as the forklift is going and putting it up. We've got other machinery in the area. Aside from maybe we didn't see a specific accident, we did see a near miss, a potential near miss, and we've also identified, okay, we might have a high congestion area right there. Sinead: There's a lot of events going on within this one particular piece of footage. Ana: Yeah. So that's why I'm so grateful for our loss control team because I'm presenting you guys with a few safety events or a few thousand, and you look at some of those samples, and you'll... We'll go into more how they look at them, but just one look at this scene and so many different events come up which we're working on getting our models to identify. But we really have such great experts on the team working with us to develop this product. Kris: Yeah. And that's a really good point because the amount of data that we're generating, it's not the normal amount of data points that the safety team normally gets. The safety team normally gets our injuries that we've already had, and other companies in the industry are trying this. But just with that clip and that video right there, we could have provided probably 50 maybe different data points to that client. So when we talk about really counting near misses and unsafe behaviors or deviations, we're getting tens of thousands of events per 10 hours of video. So that just a vast amount of data that's really coming out of this is really helping change the game because we can get such more accuracy out of it. Ana: Right. And you also get the location and we provide you with those heat maps and it's really giving a better layout of what's going on in the warehouse. So some of the risks that we are identifying span areas like human behavior, powered equipment and property. If you'll recall from the classification image I showed before, that's our humans, that's our goods, that's our forklift. So you could see that we're building into this space to get that holistic picture, which is our ultimate goal. The Computer Vision team as a whole have worked closely with customer success and loss control to create 17 proprietary risk factors. To ensure that these detectors align with customer goals, our goal is really to make warehouses more safe and also to present safety managers with impactful data and impactful recommendations so that we can get to that safer warehouse or safer environment. So if you look at the ergonomic section, you'll see that we've split waist bend in particular into high risk and repetitive waist bends. Let's get into why that is.